Metallographic Grades of Ductile Iron

Ductile iron, also known as spheroidal graphite iron or nodular cast iron, is widely used in automotive, machinery, construction, and heavy-equipment components due to its excellent combination of strength, ductility, and toughness. These properties are closely linked to its metallographic grade, which reflects the shape, size, count, and distribution of graphite nodules within the microstructure. Metallographic grading helps manufacturers evaluate casting quality and predict mechanical performance.

1. Definition of Metallographic Grades

The metallographic grade of ductile iron is primarily determined by:

Graphite nodule shape (roundness or sphericity)

Nodule count (number of nodules per mm²)

Nodule size distribution

Matrix composition (ferrite, pearlite, bainite, martensite, or mixed)

Presence of defects such as carbides, chunky graphite, or graphite degeneration

Industry standards such as ISO 945, ASTM A247, and various national specifications are widely used to classify grades.

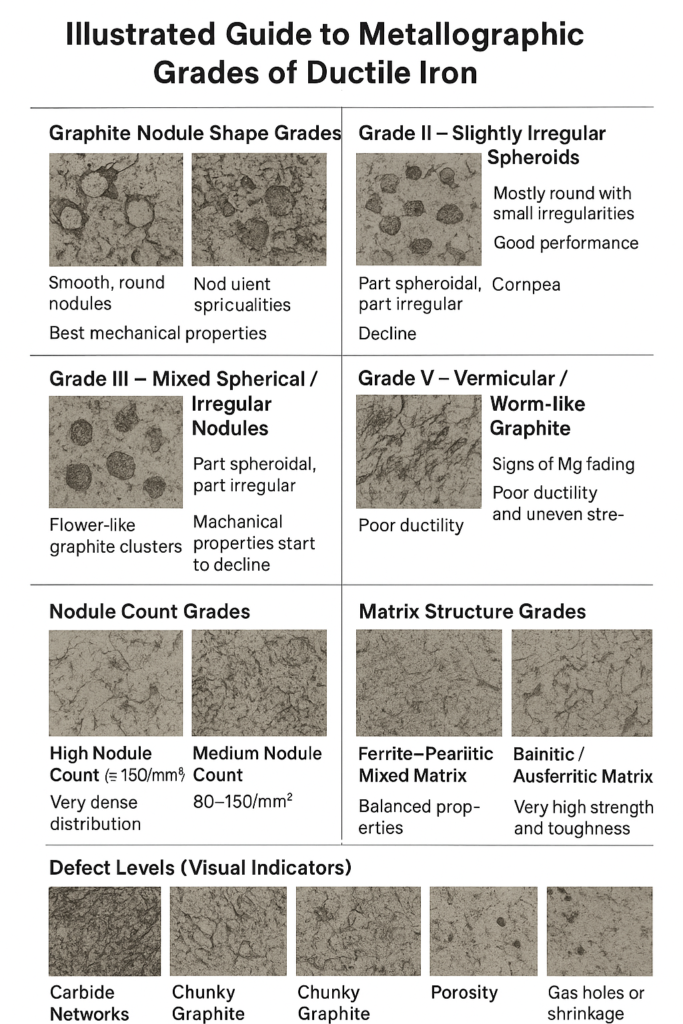

2. Graphite Nodule Shape Grades

Graphite shape is the most critical indicator of ductile iron quality. It usually falls into Grade I–Grade VI, classified by nodularity:

Grade I: Perfect Spheroidal Nodules

Round, smooth nodules with excellent nodularity (>80%).

Indicates high magnesium treatment efficiency and optimal inoculation.

Produces the best combination of strength and elongation.Grade II: Slightly Irregular Nodules

Nodules remain mostly round but show minor surface irregularities.

Nodularity typically 60–80%.

Mechanical properties are still strong but slightly reduced.Grade III: Mixed Spheroidal and Irregular Nodules

40–60% nodularity.

Usually caused by inadequate magnesium residuals or cooling variations.

Moderate strength and reduced ductility.Grade IV: Rosette Graphite

Nodules exhibit a flower-like geometry.

Nodularity drops to 20–40%.

Mechanical performance declines significantly.Grade V: Irregular Nodules / Vermicular Tendency

Elongated or vermicular shapes appear.

Indicates poor nodularization or magnesium fading.

Strength becomes unreliable; elongation is severely reduced.Grade VI: Flake-Like Degeneration

Graphite resembles grey iron flakes due to complete treatment failure.

Structure is brittle, with very low ductility.

Unacceptable for ductile iron applications.

3. Nodule Count Grades

Nodule count is directly related to strength and performance. Higher counts generally improve mechanical properties and reduce shrinkage.

Typical ranges per mm² at 100× magnification:

High Nodule Count (≥150/mm²):

Produces uniform mechanical properties; ideal for critical parts.Medium Nodule Count (80–150/mm²):

Suitable for general-purpose ductile iron.Low Nodule Count (≤80/mm²):

Leads to uneven matrix distribution and reduced strength.

A low nodule count often indicates insufficient inoculation or slow cooling.

4. Matrix Structure Grades

The matrix phase plays an equally important role in defining metallographic grade. Common structures include:

Ferritic Matrix (Soft and Ductile)

High elongation, good toughness.

Used in pipes, fittings, vibration-resistant components.Pearlitic Matrix (Hard and Strong)

Increased tensile strength and wear resistance.

Ideal for gears, automotive parts, and counterweights.Ferrite–Pearlite Mixed Matrix

Balanced properties for general engineering applications.Bainitic or Ausferritic Matrix

Achieved through heat treatment (ADI).

Extremely high strength and wear resistance.Martensitic Matrix

Very hard but brittle; generally found unintentionally after rapid cooling.

5. Metallographic Defect Levels

Metallographic grading also considers the presence and severity of defects:

Carbide networks – reduce toughness and machinability

Chunky graphite – weakens heavy-section castings

Steadite (phosphide eutectic) – forms brittle areas

Porosity or inclusions – lower mechanical performance

Each defect has its own severity level, typically ranked from Grade 1 (trace) to Grade 5 (severe).

6. Summary

The metallographic grade of ductile iron is a critical factor in determining its reliability and suitability for various applications. By evaluating graphite shape, nodule count, matrix structure, and defect levels, manufacturers can ensure consistent quality control and optimize performance.

High-grade ductile iron—characterized by spherical nodules, high nodule count, and a clean matrix—delivers superior strength, ductility, and structural integrity, making it a preferred material in modern engineering and industrial manufacturing.